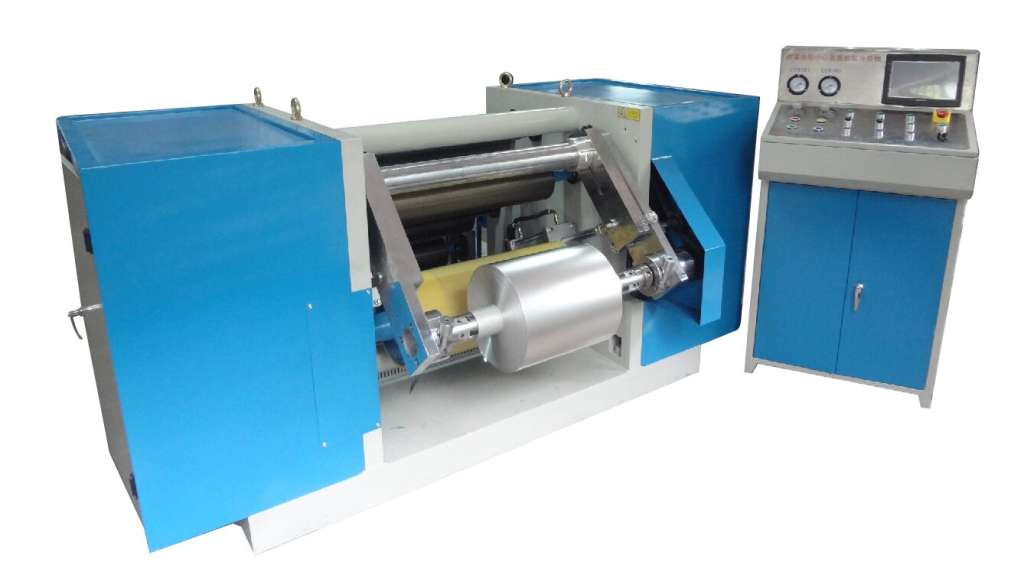

DL SL-600MV 微电脑立式单中分轴铝箔分切机

用途

该机被广泛应用于双零铝箔、单零铝箔的分切、改切、抽条、复卷及双张箔分卷等。

适用产品/业界应用

铝加工行业、食品箔、空调箔、家用箔、药品箔、电池箔、电缆箔、电子箔、电容器箔等各种卷状O态、H态纯铝箔。

主要技术特点

本机为双收料轴之中心表面卷取、复卷;采用PLC控制系统,威纶10" 触摸式荧屏, 四套日本安川伺服驱动器和安川伺服专用电机控制收放卷分切,收、放卷自动张力控制、到米自动减速停机、放卷到小卷径自动减速停机、紧急停机时放卷不松料。双收料轴分别由独立伺服马达带自动张力控制,可同时收卷大小不同直径;收料系统采用伺服系统控制,有高效率,高精度,低噪音等优点;主动力采用安川变频器配合台湾变频马达,由PLC系统控制;收卷可依卷径和米数设定,到设定卷径或米数时自动提前减速停机功能。两条包胶主动轴是由独立的动力传动,配合收卷伺服马达同步控制,当包胶中分轴外径磨损时,只需上磨床磨掉磨损表面,直到包胶中分轴的包胶完全磨损。也无需改变任何参数。分切采用圆刀及剃刀搭配,可针对不同厚度材料选择不同刀具,分切宽度由铝垫片任意调节,剃刀配合1mm间距的刀槽辊。该系统采用高可靠性电器元件、线路简单便于维护、自动化程度高,操作简便。上料方式(可选择)1.收卷轴旋转方式 2.有轴油压自动方式 3. 无轴油压自动顶锥夹紧方式

主要技术参数 |

|

机器速度 | 0-300m/min |

放卷宽度 | 600mm (300mm-1700mm) |

管芯内径 | 3〞 6〞(选配) |

放卷直径 | 600mm以内 |

收卷直径 | 600mm以内 |

分切材料宽度 | 200mm-600mm(可调) |

分切材料厚度 | 0.006-0.2mm(材料材质、厚度不同,适用设备及刀具有所区别) |

分切刀具 | 剃刀及上、下圆盘刀 |

注:以上技术参数可根据客户需求定制。

注:以上技术参数可根据客户需求定制。

DL SL-600MV MICROCOMPUTER VERTICAL DOUBLE SHAFT FOIL SLITTING MACHINE

Usage

The machine is suitable for stripping and rewinding wide of light gauge foil and medium gauge foil etc.

Applicable Product / Industry Application

Aluminum processing industry, food foil, air conditioner foil, household foil, medicine foil, battery foil, cable foil, electronic foil, capacitor foil and various kinds of roll shape aluminum foil of H states and O states.

Performance and Features

This machine is a double feed axis center surface coiling, rewinding; adopt PLC control system, touch screen Weinview 10 '', 4 set Japan YASKAWA inverter servo drivers and YASKAWA servo motor to control the rewinding cutting, collect and release control automatic tension. When arrive the distance it will deceleration. Put the volume to a small winding diameter automatic deceleration, it will not lose material when in emergency stop. The double shaft respectively by independent servo motor with automatic tension control, and rolling with different diameters; Feeding system adopts servo system control, the advantage is high efficiency, high accuracy and low noise; The active force uses YASKAWA frequency converter and Taiwan Dolin frequency conversion motor and control by PLC system; Winding can be set according to the size of the volume and the meters to set the size of the volume or the number of meters automatically in advance to slow down. The two pack of the active axis is composed of an independent power drive, and the control of the servo motor, when the outer diameter of the rubber is worn out, is only worn out the wear surface in the grinding machine until the complete wear is broken. And also do not need to change any parameter. Cutting using a round knife and razor, it can be aimed at different thickness of material selection of different tools, the cutting width is adjusted by the aluminum spacer, and the razor is within the 1mm. By using high quality electrical components, simple circuit, well automatic, convenient for maintenance and simple for operation.

Material Installation (optional) 1. Unwinding shaft rotate mode

2. Hydraulic shaft automatic mode

3.Hydraulic clamping without shaft automatic mode

Main Function Parameters |

|

Machine speed | 0-300m/min |

Machine roil surface width | 600mm(300mm-1700mm) |

Core inside diameter | 3〞6〞 (optional) |

Max. unwind diameter | Within 600mm |

Max. rewind diameter | Within 600mm |

Stripping width | 200mm-600mm(adjustable) |

Stripping thickness | 0.006-0.2mm(Material, thickness, applicable equipment and tools to be different) |

Stripping tool | Razor or round blades(opeional) |

Note: The above technical parameters can be customized according to customer demand.

Note: The above technical parameters can be customized according to customer demand.

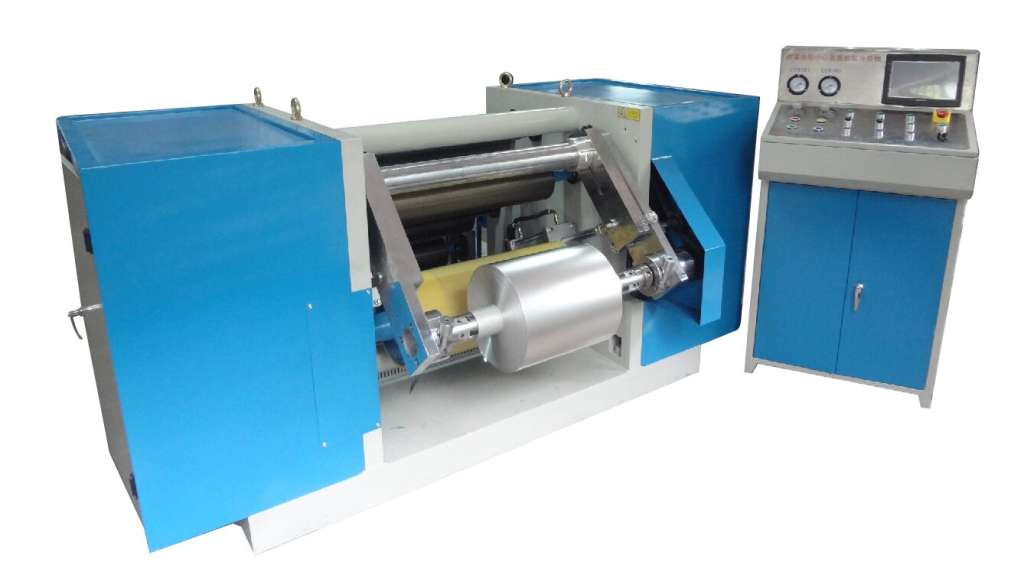

DL SL-800C微电脑盖带分条机

用途

该机被广泛应用于铝箔麦拉、铝塑复合材料、淋膜材料、PET膜、PVC膜、布铝箔编织等材料的分条、切边、复卷等。

主要技术特点

该机采用PLC、人机、矢量变频器(伺服驱动器),自动纠编器、传感器、配合台湾东菱变频专用电机、日本安川伺服电机、空油压变换系统、风冷式磁粉制动器,来控制分切过程收、放卷的速度与自动张力。到米自动减速停机、收放卷,卷径自动演算,放卷到小卷径自动减速停机、直径公差控制在±1㎜以内。收卷方式采用中心表面卷取、亦可单轴、双轴复卷,收卷轴可用互片式气账轴或机械轴、分切采用上、下圆盘刀,分切宽度由铝垫片任意调节。该系统采用可靠性电器元件、线路简单便于维护、自动化程度高,操作简便。

上料方式(可选择):1.收卷轴旋转方式 2.有轴油压自动方式 3. 无轴油压自动顶锥夹紧方式

主要技术参数 |

|

机器速度 | 0-250m/min |

放卷宽度 | 800mm (200mm-800mm) |

管芯内径 | 1.5〞 3〞 6〞(选配) |

放卷直径 | 800mm以内 |

收卷直径 | 300mm以内 |

分切材料宽度 | 5mm-750mm(可调) |

分切材料厚度 | 0.006-0.6mm(材料材质、厚度不同,适用设备及刀具有所区别) |

分切刀具 | 剃刀及上、下圆盘刀 |

注:以上技术参数可根据客户需求定制。